Technology and quality

“Our extended experience manufacturing high precision parts allows us to advise our customers on the best way to achieve the result they need”.

Our Know-How available to you

We help to develop the parts from the beginning to the end, taking measures, selecting materials and defining tolerances, planning the production and the critical points of inspection.

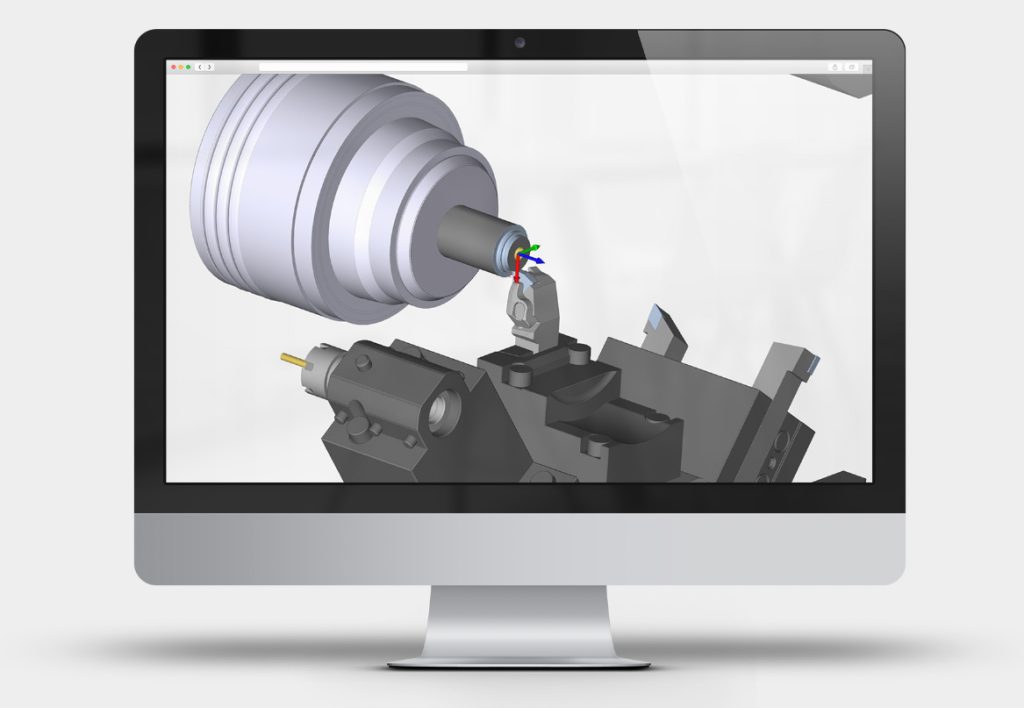

WE SIMULATE EVERY MANUFACTURE WITH A DIGITAL TWIN

Based on the solid element provided by the customer, our CAD/CAM programmes allow us to simulate its manufacturing with a digital twin. So that, when everything is alright, it goes to the actual machine, thus reducing modification times and optimising its production to the most.

We also create the control plan in a tri-dimensional machine, where we examine the maximum features possible with automatic measurings, avoiding human measuring errors.

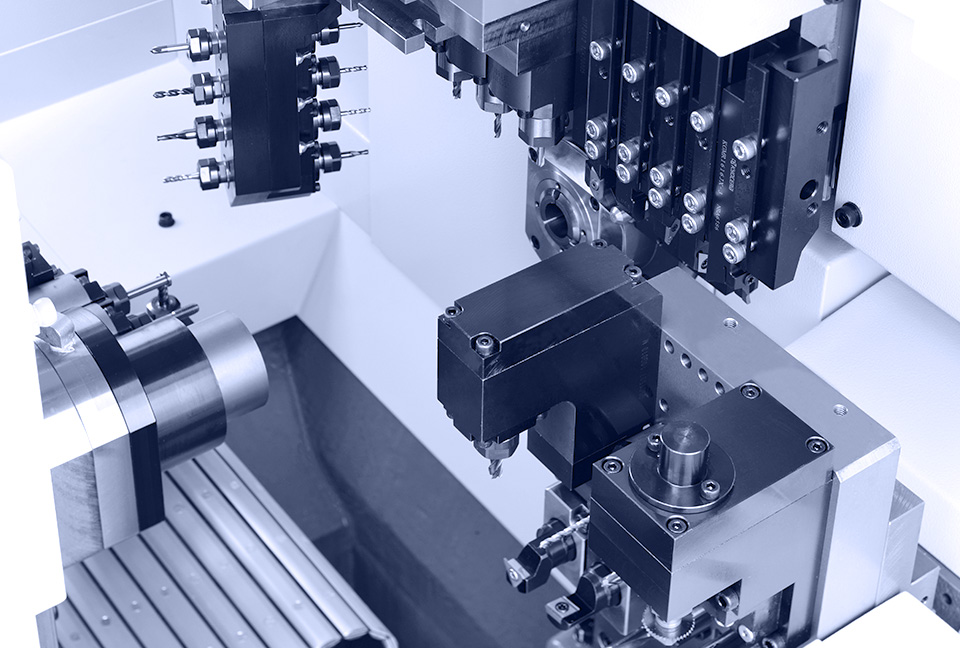

Our quality lab at your service

We have the best measuring machines in a conditioned room at 20o C not only to measure our parts but we also offer the service to our customers to measure both simple parts and assemblies.

The market keeps increasing its demands over time so we have automatic three-dimensional measuring machines that allow us to ensure measures in microns and to avoid human errors.

Data collection and their subsequent analysis are carried out with the statistics programme “MEASURLINK” of the Mitutoyo brand.

Quality Certificates

SUPRESU's objective is to achieve excellence in the quality of service to our customers. Proof of this commitment to continuous improvement are the certificates we have in terms of quality: